Metal additive manufacturing represents a cutting-edge sector in modern metallurgical production. The strength of this technology lies in the ability to produce topologically optimized metal components, thanks to exceptional design freedom and a production process that selectively adds material instead of removing it, as in traditional techniques. The Selective Laser Melting (SLM) or Powder Bed Fusion Laser Melting (PBF-LM) technology allows to produce metal parts using a bed of metal powders with particle sizes ranging from 15 to 63 μm, fused layer by layer using a focused laser beam.

The DIFILab, in collaboration with INFN, has acquired the Print Sharp 250 machine, equipped with a 500 W single-mode fiber laser at 1064 nm. The machine enables the manufacture of medium-sized components, approximately 250 x 250 x 300 mm. The equipment is set up for producing stainless steel 316L components.

The machine is provided with an open-parameter system that allows for direct control over the printing process variables, facilitating the study and optimization of the process.

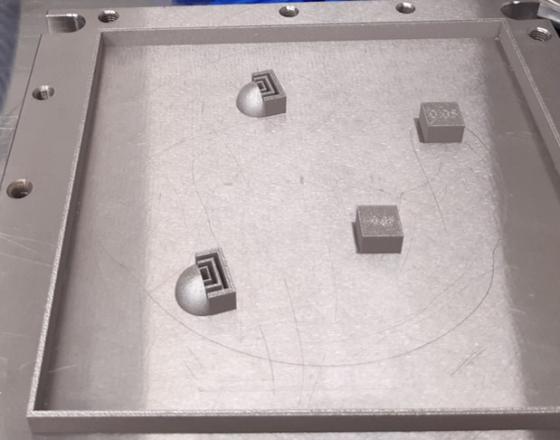

Generation of mechanical parts by metal 3D printer

The video shows the production of a layer where the infrared laser, focused on the building plane, is guided to areas where consolidated material is required by the design. In these areas, the steel 316L metal powders absorb the laser beam and melt, as evidenced by the generation of spatters.

After completing the layer, the build platform is lowered by 30 μm, and a new layer of powders is uniformly distributed over the previous one. A new cycle begins. The repetition of this cycle, layer after layer, will lead to the realization of our object, which will grow on the build platform from bottom to top.

Once the printing is finished, excess unfused powders are removed, and the plate with the printed parts undergoes a heat treatment to eliminate residual stresses resulting from the printing process. At this point, the parts are removed from the build plate and, depending on the requirements, are ready for further treatments or direct use.

The machine is operated by both DIFI and INFN personnel, allowing for a wide range of expertise and facilities, enabling management from the design to the finished product.